If you’re shopping for audio upgrades for your boat, motorcycle or side-by-side, you’ll often hear the term “marine-grade” thrown around. While the definition depends on the product category and the manufacturer, in most cases that product was designed with enhanced features that will allow it to last longer when used outdoors. In this article, we’ll take a look at some of the standard marine-specific features that let the speakers, amplifiers, source unit and wiring get wet or dirty and continue to function.

Speakers Designed for Outdoor Applications

If you have your local specialty mobile enhancement retailer upgrade the entertainment system in your boat, you’ll want to choose speakers designed specifically for outdoor use. Such companies as JL Audio, Hertz, Clarion, Wet Sounds, Kicker, Rockford Fosgate and many more offer speakers sized from 5.25 through to 8.8 inches in diameter and subwoofers from 8 to 12 inches that use materials that have been chosen to resist the destructive effects of ultraviolet energy from the sun. Likewise, these speakers are typically built around a plastic basket rather than a metal one. They may also incorporate water drainage channels into the grille.

Plastic and rubber designed for outdoor use don’t dry out as quickly as conventional ABS materials. The result is speakers that won’t fade, chalk, crack or turn yellow after only a few months.

When shopping for marine speakers and subwoofers, you’ll want to look for two common test standards. The first is the ASTM-D4329 UV exposure test. Products that have passed this test have been exposed to extremely high ultraviolet radiation levels in a test chamber. To pass the test, the materials can’t suffer from any significant degradation levels, even after 200 hours of exposure.

On a typical sunny day, the sun provides roughly 0.1 to 0.35 watts per square meter. The ASTM-D4329 test can expose products to as much as 6.5 times as much UV energy to accelerate the test process. If materials are going to fail, the intense exposure will make it happen quickly.

The second standard you’ll see with respect to speakers and subwoofers is ASTM-B177. This standard is a salt exposure test that ensures that the components used to construct the speaker won’t corrode. Test subjects are placed in a machine that exposes them to a spray or fog of typically 5% sodium chloride (NaCl). This is equivalent to almost twice as much salt as would be found in ocean water. To pass the test, the subjects need to complete it without any signs of corrosion.

Marine-Grade Source Units

Thanks to companies such as Clarion, radios explicitly designed for marine applications are now commonplace. These source options fall into two categories: marine radios and water-resistant marine radios. The marine radios are, for the most part, a car audio unit that has been modified with an upgraded display that’s easier to see in bright sunlight and a corrosion-resistant coating on the main circuit board. Some of these products also add a connection for wired remote controls, and they may include weatherband radio channels as well. More and more marine solutions offer NMEA-2000 interfacing so that they can communicate with multifunction displays from Lowrance, Garmin, Raymarine or Simrad.

The second class of marine source units is those that are designed to be weather-resistant. These products may be based on the same car audio-based circuit board but have a completely new front panel that’s designed to get wet and handle long-term UV exposure. The face of this class of radio should pass the same UV and salt testing as speakers. The front panels, when installed properly, should also have a water ingress IP rating. We’ll explain IP ratings shortly.

In most cases, the main chassis of these radios are not water-resistant. If the face of the radio isn’t sealed perfectly against the mounting surface in the boat, or if water leaks in from another source, the radio can still be damaged. If you are looking for a radio that can stay outdoors in the rain or get splashed by waves when boating, this is the type you want.

What Are IP Water and Dust Ingress Ratings?

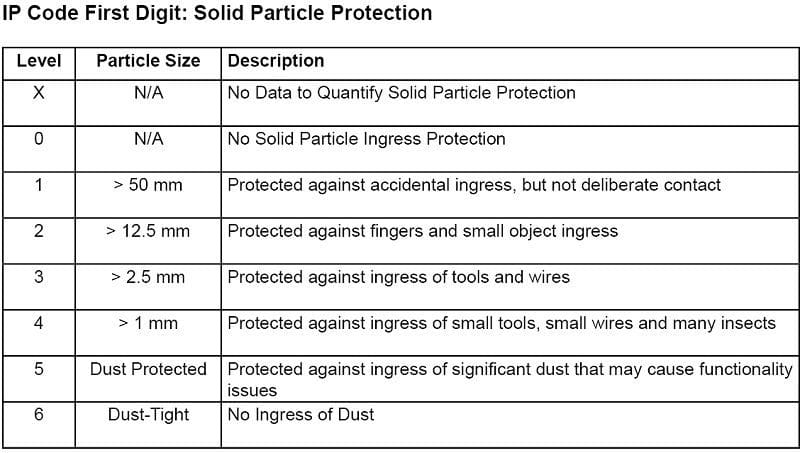

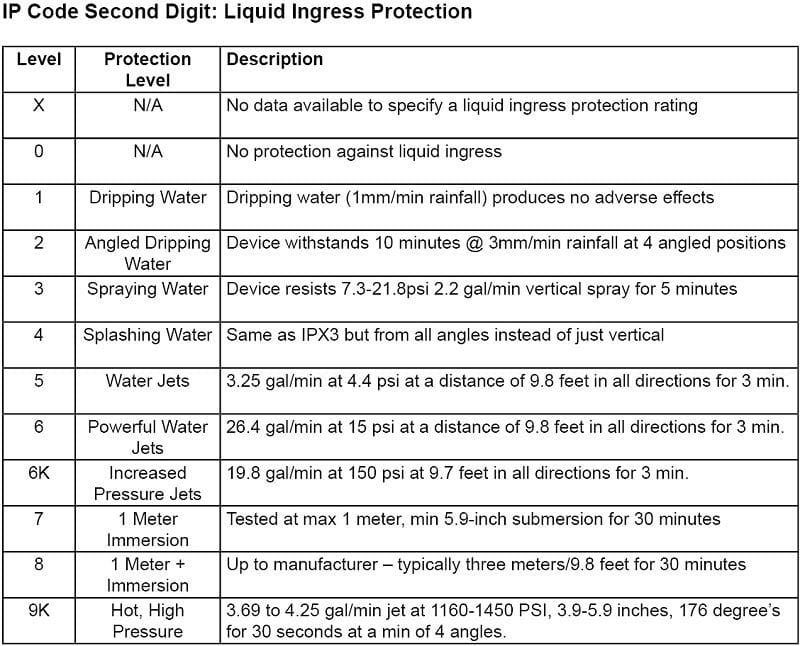

IP codes, formally known as Ingress Protection Codes or International Protection Ratings, describe a product’s ability to resist the ingress of solid particles (dust) and liquids (water) under regular use. The letters I and P are typically followed by two numbers that describe the resistance levels.

Using the information above, we can see that a product with a rating of IP68 can handle being used underwater for short periods. An iPhone 11 has an IP68 rating. If you’re shopping for a radio for your boat, motorcycle or side-by-side, the front panel will need a suitable IP rating. If you plan on submerging your side-by-side, that’s a whole different ball-game.

It’s also worth noting that a product that passes the IPX7 and IPX8 test may fail the IPX6 test. The specifications may be offered in parallel as IPX6/IPX8 – these are known as dual ratings.

Amplifiers, Fuses and Wiring

Several amplifiers on the market claim to be water-resistant. The JL Audio MX-Series marine amplifiers carry an IPX7 rating, and the Wet Sounds Stealth Micro amp claims a “completely sealed die-cast aluminum chassis for maximum protection against water and dirt intrusion.”

When you’re shopping, be wary of the difference between water-resistant and waterproof. Water-resistant products may only have an IPX rating of 3 where waterproof is likely level 7 or higher. You’ll want to look for amplifiers that have all the wiring entering and exiting the heat sink sealed in a plastic or rubber grommet. A removable panel should protect any controls on the amplifiers with foam or, preferably, a rubber gasket. Take heed: Just because an amp may be classified as waterproof, it doesn’t mean the wiring you’ve used with it will function reliably while submerged.

Speaking of wiring, and we definitely should – marine applications can be particularly challenging on speaker wire, power wire and interconnect cables, especially in saltwater conditions. Many wire manufacturers offer tinned copper conductors so that salt won’t cause the copper to corrode quickly.

A bigger concern are fuse holders and circuit breakers used in marine applications. The American Boat and Yacht Council sets the standards for safety in the North American marine industry. They have several requirements for lighting, battery switches, storage batteries, electrical propulsion systems and AC/DC electrical systems on boats. Of particular interest to our discussion is the ABYC E-11.4.15 standard that requires electrical devices that may be operated in an area where fuel or other combustible vapors are present to have an Ignition Protection rating. The test standard for Ignition Protection is SAE J1171. Devices that have passed this test will not ignite combustible gases.

In most cases, these devices are operated in a chamber filled with a highly explosive gas mixture. To pass, the gas must not ignite or explode. It’s our understanding that a spark is created in the test chamber after the standard testing is complete to confirm that the gas mixture was suitably combustible. The device under test may or may not survive this confirmation step.

If you have wiring, batteries or electronics added to an engine compartment or in the same space as fuel storage, all devices must have J1171 Ignition Protection certification.

Choose Your Outdoor Audio Upgrades Wisely

If you’re planning to have an audio system installed in a motorcycle, boat, golf cart or side-by-side, spend some time researching the suitability of the products suggested by your local specialty mobile enhancement retailer. Water intrusion protection, UV resistance and much more combine to ensure that your investment in a high-quality entertainment solution will last for many years.

This article is written and produced by the team at www.BestCarAudio.com. Reproduction or use of any kind is prohibited without the express written permission of 1sixty8 media.