It’s hard not to notice that almost every reputable car audio manufacturer now offers several ultra-compact amplifier solutions. These amplifiers are small enough to fit in the pocket of your jeans and help make installations easier when space is tight. While diminutive, they can deliver an impressive amount of power to upgrade the signal to your factory speakers or let aftermarket speakers transform your mobile sound system into an amazing listening experience. In this article, we’ll talk about how companies can cram so much power into such a small package and look at how these amps differ from conventionally sized solutions.

It’s hard not to notice that almost every reputable car audio manufacturer now offers several ultra-compact amplifier solutions. These amplifiers are small enough to fit in the pocket of your jeans and help make installations easier when space is tight. While diminutive, they can deliver an impressive amount of power to upgrade the signal to your factory speakers or let aftermarket speakers transform your mobile sound system into an amazing listening experience. In this article, we’ll talk about how companies can cram so much power into such a small package and look at how these amps differ from conventionally sized solutions.

What is an Ultra-Compact Amplifier?

While small amplifiers from companies like Sony, Soundstream, Rockford Fosgate and Linear Power have been around for decades, most of these early solutions were limited to around 20 watts of power per channels.

One of the first modern high-power compact amplifiers to make its mark in the industry was the Alpine Power Pack KTP-455U. Measuring roughly 8 by 2.5 by 1.5 inches in size, this four-channel amplifier could deliver a real-world 45 watts per channel into 4-ohm loads. Alpine marketed this amplifier as an easily integrated solution to upgrade a factory or aftermarket radio and deliver almost three times as much power to your speakers.

One of the first modern high-power compact amplifiers to make its mark in the industry was the Alpine Power Pack KTP-455U. Measuring roughly 8 by 2.5 by 1.5 inches in size, this four-channel amplifier could deliver a real-world 45 watts per channel into 4-ohm loads. Alpine marketed this amplifier as an easily integrated solution to upgrade a factory or aftermarket radio and deliver almost three times as much power to your speakers.

A few years later, Rockford Fosgate introduced its Boosted Rail Technology series of amps. These amps use a unique and creative power supply design that was different from all the other solutions on the market. From a power-production perspective, the four-channel PBR300X4 could crank out 75 watts of power into a 4-ohm load and had a footprint of only 6.75 by 4.25 inches.

A few years later, Rockford Fosgate introduced its Boosted Rail Technology series of amps. These amps use a unique and creative power supply design that was different from all the other solutions on the market. From a power-production perspective, the four-channel PBR300X4 could crank out 75 watts of power into a 4-ohm load and had a footprint of only 6.75 by 4.25 inches.

Fast forward five years, and there are dozens of companies with small, high-power amplifiers available. You can choose from four- or five-channel solutions to upgrade your sound system, and most offer a roughly 300-watt subwoofer amp to add big bass without taking up much space. Several models include water-resistant designs that make them ideal for marine, motorcycle and powersports applications.

Big Power in an Amazingly Small Package

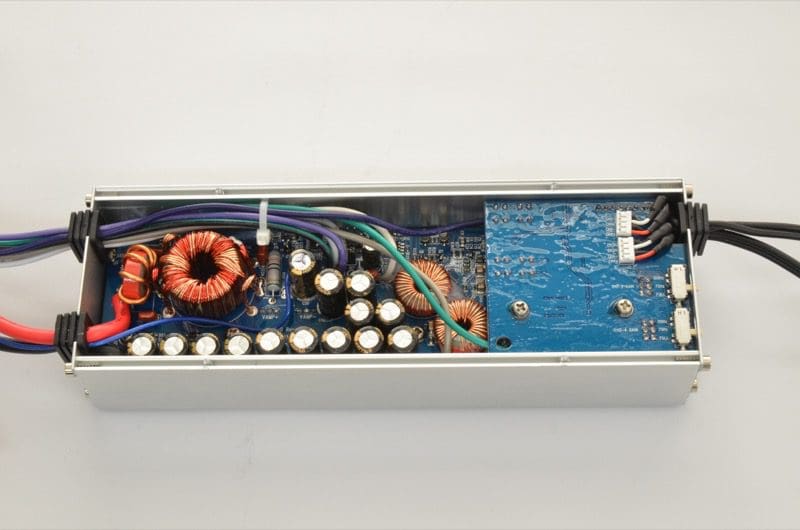

Amplifier size is determined by two factors: how much space is required to house the components needed to make the amp work, and how much heat sink does the design need to dissipate heat reliably under all conditions.

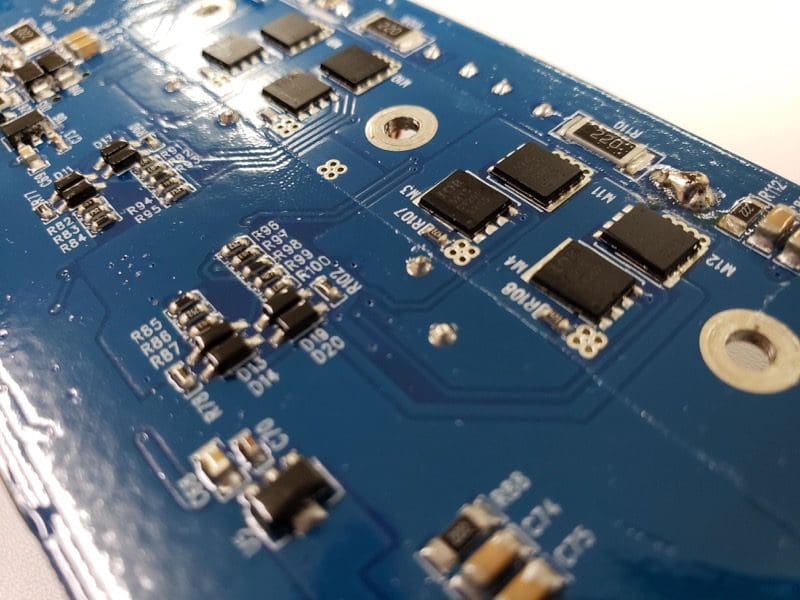

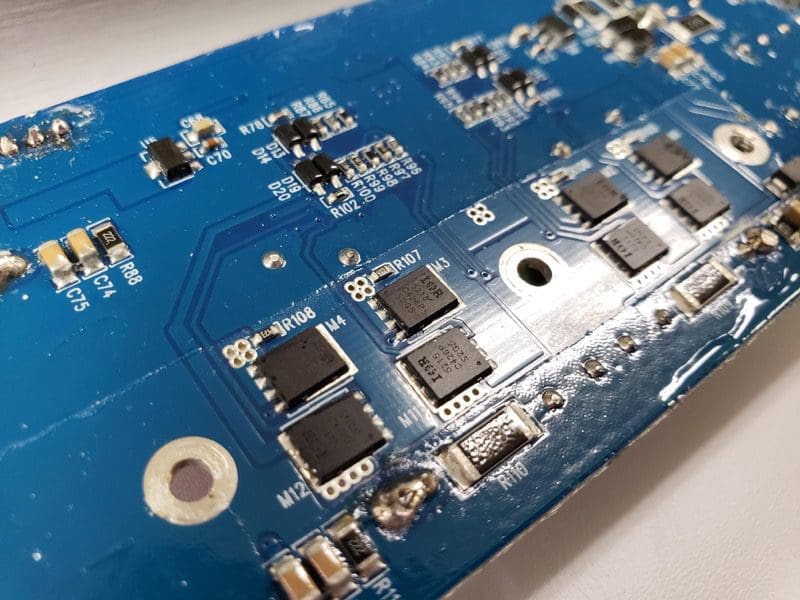

One of the biggest technological advances that have allowed amplifiers to become so small is surface-mount devices. Thanks to subminiature resistors, capacitors, diodes, transistors and microcontrollers, circuits and their components can fit in half or a third of the space they used to require. Think about your smartphone — it has more processing power than desktop computers from 10 years ago, yet fits comfortably into the palm of your hand or a shirt pocket. By comparison, the computers that took the space shuttles into orbit ran at about 1.2 million instructions per second (MIPS) and had a total memory of a couple of megabytes. The Apple A11 processor found in the iPhone X can manage a jaw-dropping 600 billion instructions per second. With that said, the Apple CPU isn’t designed to handle the rigors of outer space and prolonged exposure to radiation — so keep that in mind if you’re planning a trip to Mars with our buddy Elon Musk.

The surface-mount Metal Oxide Semiconductor Field Effect Transistors (MOSFETs) used in the power supplies of these ultra-compact amplifiers have also allowed the amps to shrink in size dramatically. You can fit four of these devices on the end of your finger, and each one is capable of passing 50 amps of current. Thirty years ago, a single 50-amp transistor would have been bigger than all four of these modern devices.

Another technology that has reduced amplifier sizes is multilayered circuit boards. Four-layer boards provide significantly more options for connectivity among the devices in the circuit and reduce the space required for signal traces.

Finally, high-speed Class-D amplifier designs help to reduce current consumption in the output stage of the amp. Class-D audio amplifiers operate by switching the output devices on and off at extremely high speeds, and varying the duty cycle (on vs. off periods) recreates the original audio waveform. Because the devices are either on or off, they spend less time acting as a resistor and, subsequently, waste less energy as heat.

Are Compact Amplifiers the Perfect Solution?

With any benefit, there are often drawbacks. For ultra-compact amplifiers, three limitations need to be considered: cooling capacity, features and noise. As we mentioned earlier, fitting lots of parts into a small package is much easier, thanks to surface-mount devices and multilayered circuit boards. The drawback of a small amp is that it still needs a heat sink to the cool the switching devices. If we reduce the heat-sink area for a given power level, the amp will be more prone to overheating when pushed hard. You might be fine for one or two songs, but you likely won’t be able to jam on these at full-blast on a hot summer’s day in Arizona or Texas without them going into protection.

The features included with an amplifier are often based on the space available for controls and switches. If you want high- and low-level inputs, adjustable high-, low- and bandpass crossovers, infrasonic filters, signal summing, individual sensitivity controls, bass-boost circuits and remote level controls, you need lots of space. In an ultra-compact amplifier, that space simply doesn’t exist. As such, most of those features won’t be found on this class of amplifiers.

Finally, we need to talk about noise. Noise, or more specifically, signal-to-noise ratio (S/N Ratio) describes how much background noise (heard as hiss) is added to an audio signal when it passes through a device. The power supply and Class-D output stage of an amplifier produce a lot of high-frequency electrical noise. In a conventional and physically large amplifier design, these noisy circuits can be located physically and electrically far away from the sensitive input and signal gain stages of the amp. When we shrink an amplifier’s size by 30 percent, everything is much closer and thus more of this noise is added to the output signal.

Let’s look at five different four-channel Class-D amplifiers to compare noise levels relative each amplifier’s physical size.

Comparison of Four-channel Amplifier S/N Ratio

Amplifier Footprint Power / Channel S/N Ratio at 1 Watt

Square Inches Watts A-Weighted

Amp 1 26.76 50 >68 dB

Amp 2 41.99 70 >70.4 dB

Amp 3 60.41 75 >84 dB

Amp 4 68.07 75 >84 dB

Amp 5 89.03 150 >88.2 dB

As you can see, larger amplifiers add less noise to the output signal. While none of these specifications is atrocious, you will be able to hear a little hiss from the first two amps between songs and likely won’t on the top three amps. Of course, the third amp has a 50 percent larger footprint (length times width) than the second amp, so pick your poison appropriately.

Ultra-Compact Amplifiers Offer Unique Installation Solutions

If you are trying to add an amplifier to a motorcycle or a side-by-side and finding space for the amplifier is a concern, then, by all means, choose one of the many ultra-compact amps that are available. With that said, if you have a little extra space, larger amps offer better noise performance and more features. In this case, you get an audible improvement in performance by investing a little more money.

If you are interested in upgrading your mobile sound system, drop by local specialist mobile electronics retailer and speak to one of their product experts. They can provide you with several options to dramatically improve the sound quality and volume level of your existing system.

This article is written and produced by the team at www.BestCarAudio.com. Reproduction or use of any kind is prohibited without the express written permission of 1sixty8 media.