A digital signal processor, or at the very least some type of equalizer, is pretty much a requirement when it comes to creating a car audio system that will have realistic tonal balance. There are dozens of methods to configure and tune these processors, and each has benefits and drawbacks. What seems to be an ongoing issue is the need to have someone with the proper training and tools execute the process. The so-called “Golden Ears” method doesn’t work. This article will look at some of the expertise required to complete this process, along with the equipment necessary to deliver accurate and reliable results.

Is It Tuning?

Describing the process of setting up a digital signal processor for a car has long been described as tuning. While technically correct, this term carries the implication that it’s an art form rather than a process. We think a better word to describe the process is calibration. The technician working on your car will take a measurement, perform an adjustment and repeat the process until the final goals are achieved. This process doesn’t require a unique skill set but does require proper tools and training.

The Engine Management System Analogy

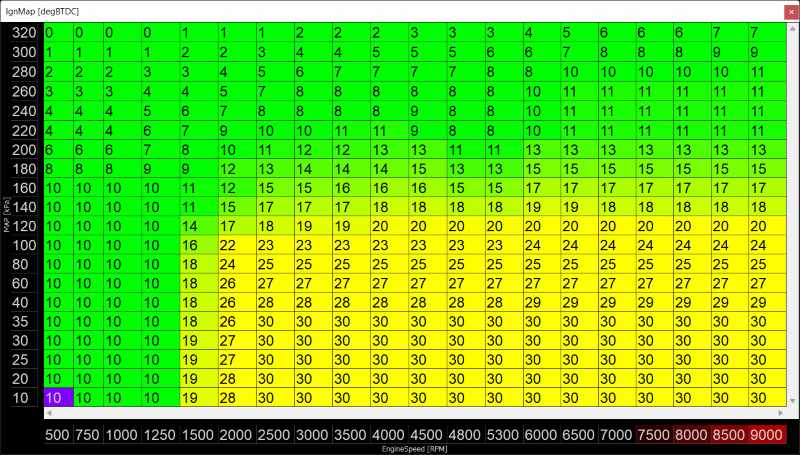

If you’re into cars or trucks, then you’ve likely seen the thousands of options available to set up an electronic ignition and fuel injection system for a modern vehicle. At the most basic level, ignition timing and fuel delivery maps are required to let the engine know how much gas to squirt into the cylinders and when to fire the spark plugs. These three-dimensional tables aren’t much different from the signal delay, output level and equalization settings in a car audio DSP.

Start with the Basics

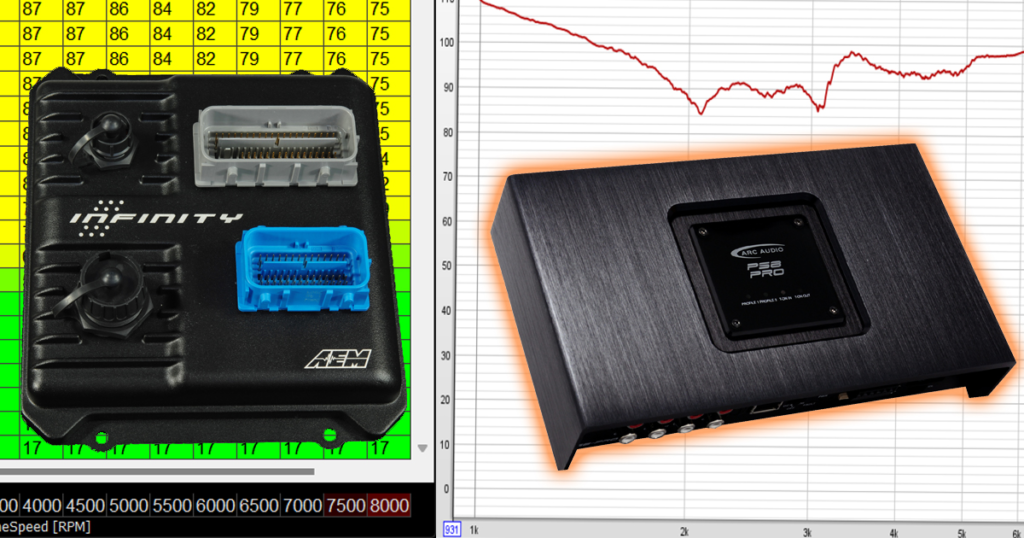

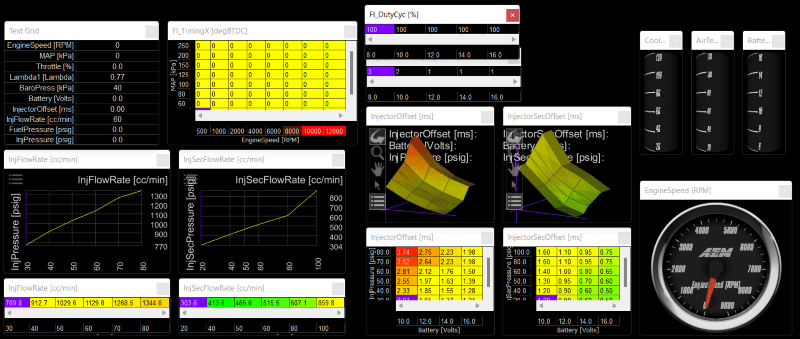

If you buy a stand-alone engine management computer for a project car, something like an AEM Infinity or Holley Terminator X, the starting point is to tell the system what it will be controlling. Your technician needs to set up the crank position sensor and confirm that it’s reading the true mechanical top-dead-center of your engine. Next, they’ll need to configure fuel injector information to let the computer know how much fuel they can flow. They will also need to set up any O2 sensors and a MAP sensor. If there are fuel and oil pressure, temperature, cam position and throttle position sensors, the list goes on and on. The tech will need to understand the calibration of each of these sensors and enter that into the software long before he or she tries to start the engine for the first time.

On a DSP, your mobile enhancement technician needs to set up the signal inputs and configure how those will be routed to the channels of the processor. Next, they have to set crossovers for each channel based on the speakers in the vehicle. This requires an understanding of the speakers’ capabilities, where they are installed and what drivers are being used in adjacent frequencies. They also need to understand what type of crossovers to use to deliver the smoothest frequency response while protecting the speaker from damage. On the latter, how loudly the system will be played has a significant role in setting filter frequencies.

The technician can now move to set signal delays. Whether they use a tape measure or an acoustic technique using impulse tones, these settings need to be close to right before the frequency response calibration process starts.

System Calibration Ensures Accurate Performance

Once the engine is up and running, it’s time to start making measurements and adjusting the fuel and timing tables. The engine or vehicle will need to be installed on a dynamometer to provide the engine with different loads at different speeds. The technician will work through the fuel map while reading from one of several wide-band oxygen sensors to calibrate the amount of fuel the injectors feed into the engine. At the same time, the ignition timing needs to be adjusted for a similar table to tell the spark plugs when to fire in each revolution of the engine. Getting these settings right works in conjunction with fuel delivery, as firing the spark plug at the wrong time might result in not all the fuel being burned. Too much timing or too much ignition advance can damage the engine. The technician will monitor power production in each table cell (engine speed versus load) to optimize the system.

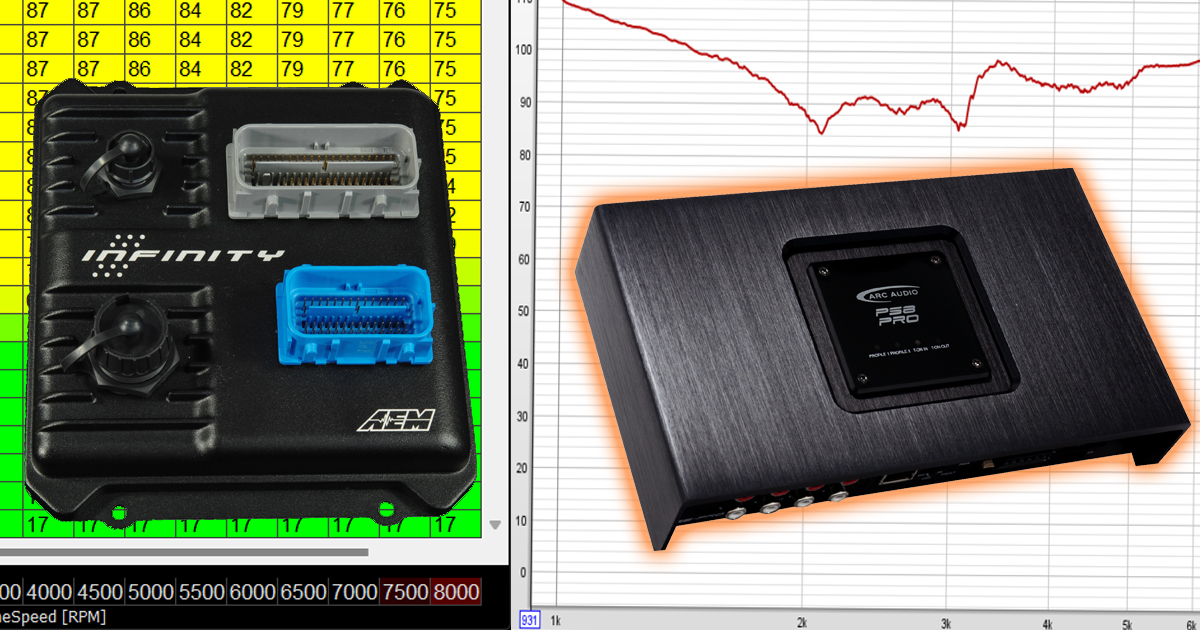

Back to our audio example, once the system is up and playing, the technician will use a calibrated audio analyzer to examine the frequency response of each channel in the audio system. Again, they are looking to ensure that reflections and resonances caused by the vehicle interior haven’t changed the sound at the listening position.

Since it always happens, they use graphic or parametric equalization to compensate for these changes. But, just as with the engine management system, too much adjustment can also lead to speaker damage. Likewise, the technician needs to examine and fine-tune the interaction between speakers running in adjacent frequency ranges or on the other side of the vehicle. Those with the tools and training to do so will also measure the phase response of the system to further fine-tune the calibration. Properly configured phase response is part of what helps to produce “up front bass” in an audio system with a subwoofer in the cargo area or behind a seat.

Calibration Equipment is Crucial

You’ll note investment in equipment is required to complete either calibration process. On the engine side, a wide-band oxygen sensor and a dynamometer are necessary to evaluate how each change to fuel delivery and timing affects the engine’s performance.

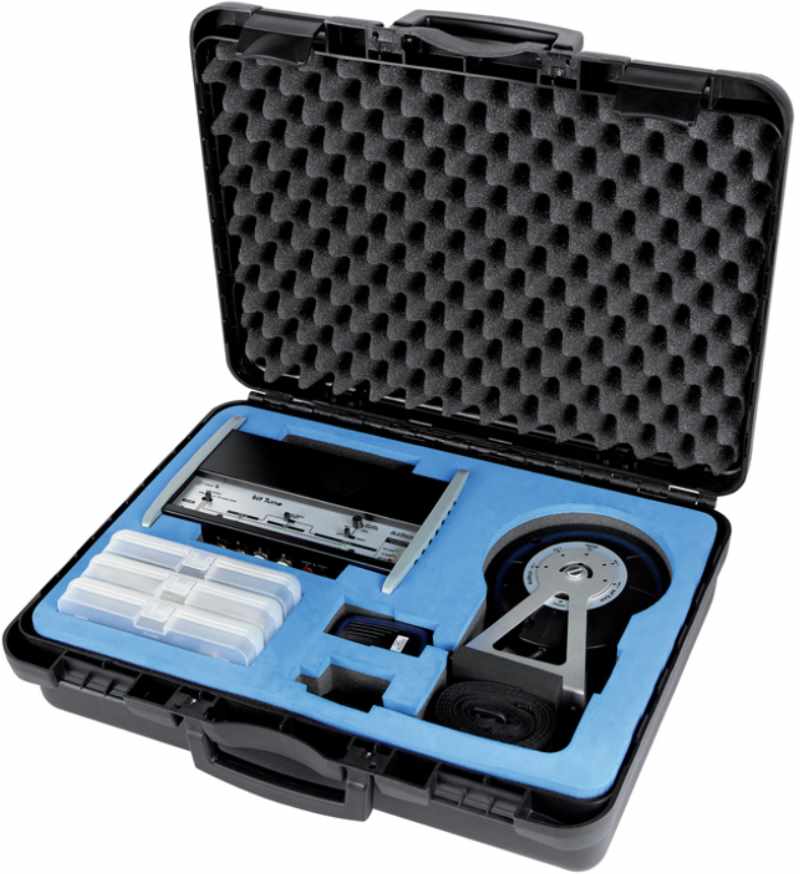

A calibrated real-time analyzer and appropriate test tones are the primary tools on the audio side. In addition, an audio analysis system that includes a time-referenced measurement is necessary for more advanced tuning with phase evaluation.

What if someone tries to calibrate either system without these tools? Is the infamous “butt dyno” going to be able to pick out a deficiency in a particular cell of a fuel or timing map? Would ¼-mile timeslips let them know if day-to-day drivability is smooth? Tools are a necessity to ensure proper optimization.

Is It Right or Wrong?

In an engine management system, lack of optimization might reduce the maximum power that the engine can produce and reduce fuel efficiency. If it’s too far out of what’s ideal, the engine can overheat, or in the other direction, pre-detonation or knock might occur that can damage a piston. Ideally, the engine should run smoothly and deliver excellent power and fuel economy at all load conditions

If things aren’t configured properly in a car audio system, there is a chance that a speaker or number of speakers could be damaged by overdriving them. In most cases, the audio system won’t sound right. For example, voices might not sound realistic. They might be too bright or have too much bass information. If the delay and level settings aren’t correct, vocals and instruments may sound as if they are coming from the incorrect location on the soundstage, the sounds might be blurred, or there may not be a soundstage at all.

Choose an Expert to Calibrate Your Car Audio System

Just as you wouldn’t let an amateur calibrate a high-performance race car engine, it’s paramount that you choose a technician with the experience and tools required to design, integrate, configure and calibrate your car audio system. If you choose the wrong shop and technician, you may not get the most from your investment, and the system might not sound impressive. In a worst-case scenario, the speakers could be damaged if you turn up the volume. So make sure you audition several systems the shop has created and make sure they can deliver those same results in your car or truck before you agree to hire them.

This article is written and produced by the team at www.BestCarAudio.com. Reproduction or use of any kind is prohibited without the express written permission of 1sixty8 media.